Design the Extraction Process: projecting into the future

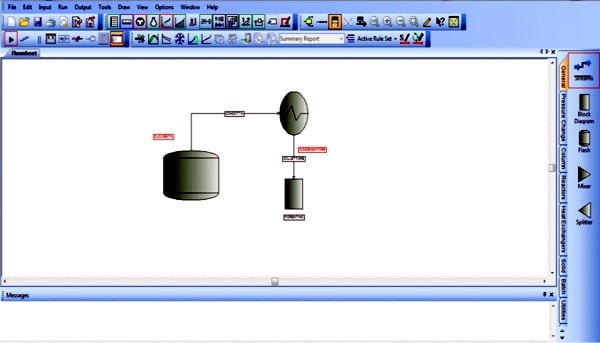

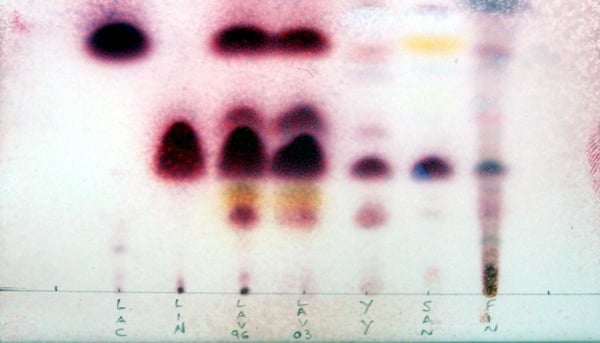

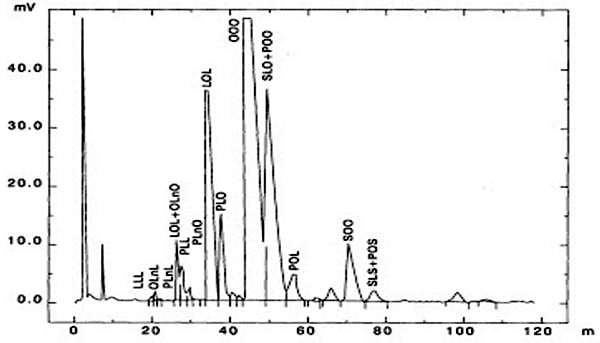

At Casalvento electronics, chemistry and CAD have been used to develop efficient and non-polluting extraction systems. The plants have been designed with the use of special CAD software and industrial chemical fitting to obtain the best quality of the extracts.

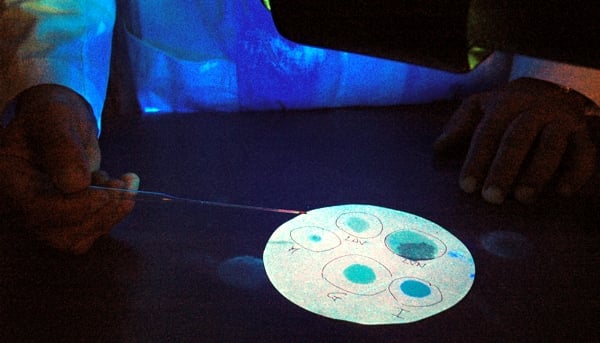

Specific sensors based on optoelectronic technologies, piezoelectric and magnetostrictive are connected to PLC control-core to handle each process step of steam and solvent distillation.

We are passionate about producing extracts and distillates and we have applied engineering process to our production chain to ensure the minimum environmental impact in an area where energy consumption is of great value.

The temperatures control, pressures and flows at all extraction stages are essential to obtain higher quality extracts at sustainable costs.

New materials, suitably chosen and assembled according to a new processing method were also the 3rd Millennium protagonists of the alchemy.